The mechanical seal ring is one of the most fundamental parts of the mechanical seal. The quality of the seal ring identifies the life span and also securing performance of the seal to a huge level.

Properties of carbide rings:

1. The hardness is extremely high, which is several times that of other materials.

2. Strong bending resistance, no bending deformation.

3. Polishing process, high wear resistance, long service life.

4. Strong corrosion resistance, can seal corrosive media.

Machining of carbide rings:

1. Use the best quality raw materials and press them into a ring shape through a mold.

2. Vacuum furnace sintering to obtain high-strength, high-hardness carbide ring blanks.

3. Grinding and polishing to improve surface finish and achieve mirror effect.

4. Quality inspection, no defective products are allowed.

Ningbo Langsun Tungsten Carbide Co., Ltd. has rich experience in production and production. We have our own processing plant and are fully equipped with excellent equipment. We can provide not only rough but also finished products. During the production process, we have strict inspections at every step to ensure stable product quality and excellent performance. We will also provide customized services to provide you with the most suitable product according to your purpose, so that the product can exert its maximum performance. We have experienced and highly skilled engineers, you can have full confidence in our products. If you are interested in our products, please contact us.

Cobalt Binder Grades

Grade | Binder (Wt %) | Density (g/cm3) | Hardness (HRA) | TRS (>N/mm²) |

YG6 | 6 | 14.8 | 90.0 | 1520 |

YG6X | 6 | 14.9 | 91.0 | 1450 |

YG6A | 6 | 14.9 | 92.0 | 1540 |

YG8 | 8 | 14.7 | 89.5 | 1750 |

YG12 | 12 | 14.2 | 88.0 | 1810 |

YG15 | 15 | 14.0 | 87.0 | 2050 |

YG20 | 20 | 13.5 | 85.5 | 2450 |

YG25 | 25 | 12.1 | 84.0 | 2550 |

Nickel Binder Grades

Grade | Binder (Wt %) | Density (g/cm3) | Hardness (HRA) | TRS (>N/mm²) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Typical Tungsten Carbide Grade Mechanical Properties for Mechanical seal rings

| Grade | Main Chemical Composition(wt%) | Modulus Of Elasticity (KN/m㎡) | Compressive Strength (N/m㎡) | Thermal Conductivity (W/m-K) | Coefficient Of Thermal Expansion | ||||

| WC | Co | Ni | TiC | Mo | |||||

| YG6 | 94 | 6 | - | - | - | 630 | 5500 | 100 | 5.5×10-6/ K |

| YG8 | 92 | 8 | - | - | - | 590 | 5200 | 90 | 5.8×10-6/ K |

| YG15 | 85 | 15 | - | - | - | 530 | 4600 | 70 | 6.2×10-6/ K |

| N100 | 94 | - | 6 | - | - | 600 | 4500 | 90 | 5.3×10-6/ K |

| N200 | 92 | - | 8 | - | - | 570 | 4300 | 80 | 5.2×10-6/ K |

| TIP | 81.5 | 8.5 | 10 | - | 530 | 4700 | 70 | 5.6×10-6 /K | |

| QT200 | 25 | - | 15 | 52 | 8 | 400 | 3400 | 25 | 7.8×10-6 /K |

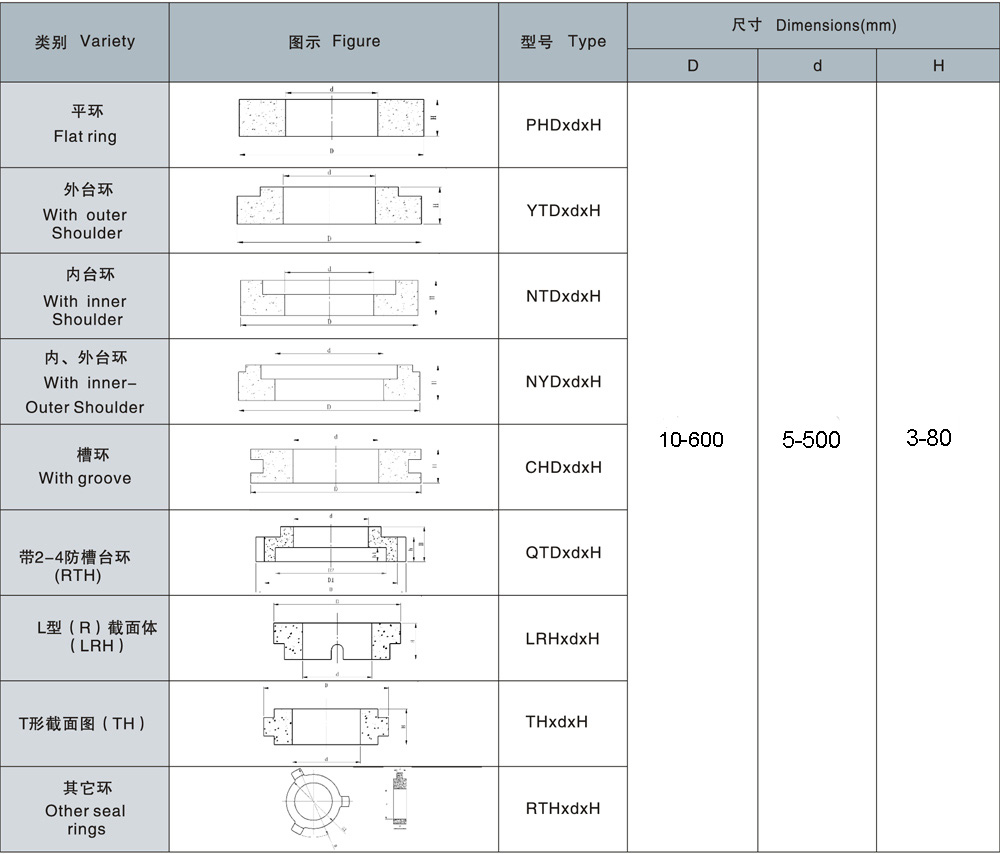

Typical Mechanical Seal rings drawings.