Langsun Carbide has rich experience in producing tungsten carbide seal rings, we have supplied seal rings for clients all over the world for a long time. Every link of the products we generate has rigorous inspection, high precision, little tolerance, stable quality and also performance. Before sales, we can provide specialist suggestions according to the products you need. After sales, if the products are harmed, we can give you with replacement services. We have good supply ability and punctual shipment time, lots of huge ventures throughout the globe are our customers. If you have an interest in our products, please do not hesitate to contact us, we will reply to you within 1 day.

Why choose us:

1. Can produce and provide all kinds of sealing rings, both blank and finished products can be provided

2. The processing equipment is complete, the workmanship is good, and the product quality is guaranteed

3. Can be manufactured according to user drawings

4. Using 100% high-quality raw materials, excellent performance

5. Cost-effective, affordable

Cobalt Binder Grades

Grade | Binder (Wt %) | Density (g/cm3) | Hardness (HRA) | TRS (>N/mm²) |

YG6 | 6 | 14.8 | 90.0 | 1520 |

YG6X | 6 | 14.9 | 91.0 | 1450 |

YG6A | 6 | 14.9 | 92.0 | 1540 |

YG8 | 8 | 14.7 | 89.5 | 1750 |

YG12 | 12 | 14.2 | 88.0 | 1810 |

YG15 | 15 | 14.0 | 87.0 | 2050 |

YG20 | 20 | 13.5 | 85.5 | 2450 |

YG25 | 25 | 12.1 | 84.0 | 2550 |

Nickel Binder Grades

Grade | Binder (Wt %) | Density (g/cm3) | Hardness (HRA) | TRS (>N/mm²) |

YN6 | 6 | 14.7 | 89.5 | 1460 |

YN6X | 6 | 14.8 | 90.5 | 1400 |

YN6A | 6 | 14.8 | 91.0 | 1480 |

YN8 | 8 | 14.6 | 88.5 | 1710 |

Typical Tungsten Carbide Grade Mechanical Properties for Mechanical seal rings

| Grade | Main Chemical Composition(wt%) | Modulus Of Elasticity (KN/m㎡) | Compressive Strength (N/m㎡) | Thermal Conductivity (W/m-K) | Coefficient Of Thermal Expansion | ||||

| WC | Co | Ni | TiC | Mo | |||||

| YG6 | 94 | 6 | - | - | - | 630 | 5500 | 100 | 5.5×10-6/ K |

| YG8 | 92 | 8 | - | - | - | 590 | 5200 | 90 | 5.8×10-6/ K |

| YG15 | 85 | 15 | - | - | - | 530 | 4600 | 70 | 6.2×10-6/ K |

| N100 | 94 | - | 6 | - | - | 600 | 4500 | 90 | 5.3×10-6/ K |

| N200 | 92 | - | 8 | - | - | 570 | 4300 | 80 | 5.2×10-6/ K |

| TIP | 81.5 | 8.5 | 10 | - | 530 | 4700 | 70 | 5.6×10-6 /K | |

| QT200 | 25 | - | 15 | 52 | 8 | 400 | 3400 | 25 | 7.8×10-6 /K |

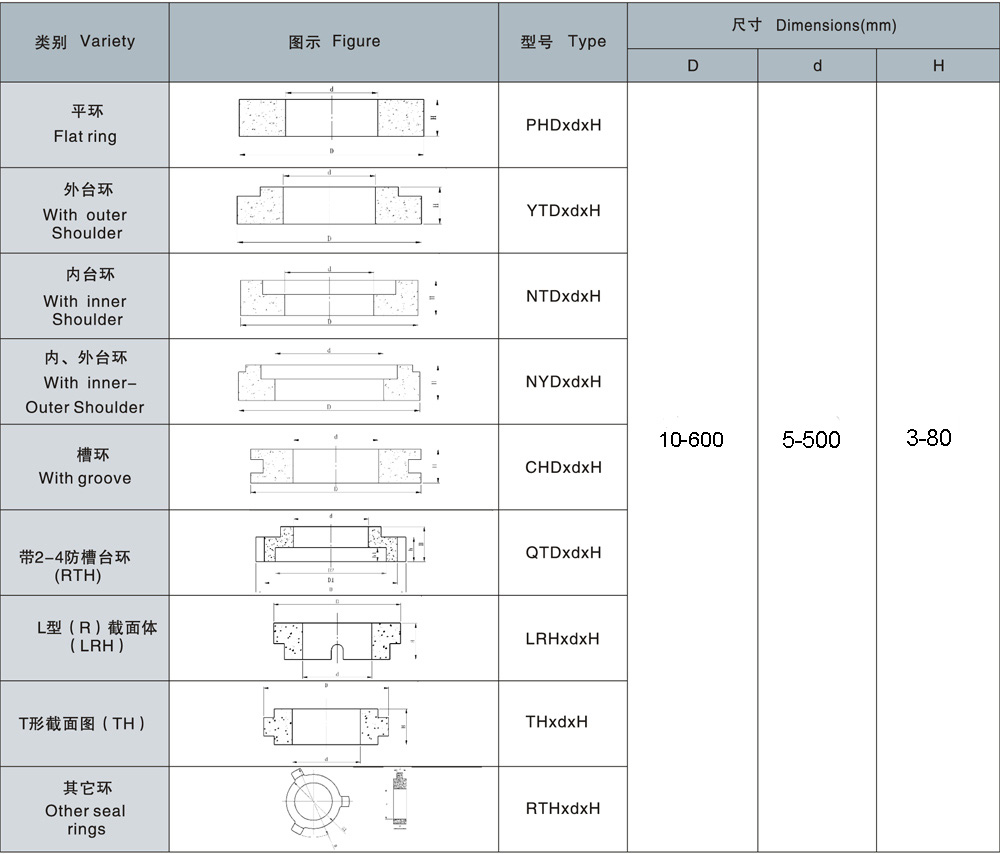

Typical Mechanical Seal rings drawings.